By Robert Buchholz

My 1968 Jeepster was having an issue pulling fuel from the tank. If I let it sit for more than a couple of days, it would often require starting the engine with a splash of fuel in the carburetor, or starting fluid to get enough suction to pull fuel. Even then, you would see pulsing in the clear plastic fuel filter with the occasional splash of fuel. There are several possible reasons for this to happen. First is a bad fuel pump, but I had replaced my fuel pump in the past because I thought this was my issue. However, to rule this out this time, I disconnected my fuel line from the tank at the over-engine metal line, and connected it to a fuel hose going to a fuel can. The pump was able to pump fine. The next possibility was that the nylon fuel line had developed a pinhole, and the pump was sucking air. The final possibility was that the pickup tube in the fuel tank had developed a pinhole. This could hypothetically be determined by filling up the tank and if the problem stopped, then the problem would be the pickup tube. I didn’t want to fill the tank up, only to find out that I would then need to drop it anyway, so I made the command decision to drop the tank and replace the 50+ year old nylon fuel lines, and I would assess the tank and pickup tubes with the tank removed.

Materials needed for this project:

- Fuel line(s)

- The V6 has a 5/16″ (~8mm) pickup line and 1/4″ (~6mm) return line

- The F4 only has the pickup line

- You can get a kit from one of the parts suppliers on the links page, or buy the line in coils. You will need at least 10 ft of each required size for your vehicle.

- Hose Clamps (optional, but many may be rusted out)

- Mounting bushings (optional, but mine were dry rotted after 50+ years)

- Mounting Hardware (optional, but often the lock nuts should not be re-used, and it is cheap insurance)

- Replacement hoses (optional, Again 50+ years have their effect on the rubber, it is cheap insurance to replace these items while they are easy to reach.

- Spray paint and Spray undercoating (optional, I used this as preventative maintenance on the tank.)

NOTE: It should go without saying, but this process opens your tank and fuel system to the air, and fuel vapors WILL be present. Make sure you have no open flames or sparks around while you are working. Do this work at your own risk. Any damage to yourself or your vehicle is your responsibility.

Removing the tank is the first step. I started by disconnecting the fill tube from the back of the tank, and putting a line in and used an electric pump to drain any left over fuel from the tank. There are two styles of tank, the rear fill, which I have, and the side fill, which seems to have been introduced later. While the tank is still bolted on, remove the vent tube as well. Once the vent tube is removed, disconnect the fuel lines if you can reach them. There should be a bullet connector that connects your fuel gauge, disconnect it. My connector was so corroded, and there were signs of previous hackery in the wiring, so I cut the wire and replaced a large amount of it with new wire and connected it back with a heat-shrink butt connector. Next, support the tank with a floor jack or transmission jack. Although the tank itself is light, fuel is about 6 lbs per gallon (0.7 Kg per liter), and it is unlikely that all fuel is removed from the tank, so it is important to have mechanical help to support the weight. Remove the 3 nuts from the bottom of the tank supports. These nuts should be metal lock nuts, so you will have to apply effort all the way off. Be careful, if the tank was mounted incorrectly, as mine was, it may come loose at this point. Remove the bottom washers, rubber bushings, etc. At this point the tank should be setting on top of the mounting brackets (mine wasn’t). To make it easier to remove from the frame, remove the mounting bolts from the passenger rear mounting bracket. With this removed, you should be able to slide the tank back a few inches to clear the passenger front bracket, and lower the passenger side down and move the tank off of the driver side bracket. If you can, have a second person help you with the lowering of the jack while you maneuver the tank. Once the tank is down a few inches, you can disconnect any wires or hoses you couldn’t reach before. At this point the tank should be free from the vehicle, and can be pulled out and placed in a safe place. This is also a good time to pour out any residual fuel from the tank.

At this point, the nylon fuel lines should be easily removable. You will find that the lines are routed through metal tabs that are spot welded to the floor. Disconnect the lines from the over engine metal lines, and carefully pull the lines back from underneath the Jeep. Be careful with the metal tabs, as they can easily be broken off. I eased my lines back through them without bending them much. Once the old fuel lines are removed, Carefully feed the new fuel lines in from the back, leaving the excess on the tank side. The most difficult part is routing the fuel lines up over the transmission and bell housing. Reconnect the fuel lines to the over-engine lines. I don’t have an F4 engine Jeepster to compare, but from the parts manual, it appears the line runs all the way up to the front in the frame rail, and crosses over under the front of that engine.

Now that the fuel lines are in place, it is a great time to assess the fuel tank. I pulled my sending unit and fuel return. Once outside of the tank, you can validate if the sending unit is good if you were having any gauge issues. Connect an ohm meter to the stud and the plate. Move the lever of the float up and down, and you should see the value changing. My sending unit ranged from approximately 20 ohms full to 80 ohms empty. New units say 0-7 full and 70 to 80 empty, so mine might be a little off, but the fact that it varied indicates that it will likely work at least partially. With the sending unit out, I was able to assess the interior of the tank and the pick up tube. Everything looked good in my tank, but here is where you could do a tank liner or other repairs, or if necessary, replace the tank. Something I didn’t do, but should have was verify my float still floated. Many of the old units like mine used a cork float, which can get logged with fuel over time. Make sure you clean the surfaces on the tank and sending unit and put in a new gasket. I also chose to do some exterior maintenance on my tank. I stripped the flaking undercoating and wire-brushed off the dirt and debris. I then put on a rust-stop paint. On top of the paint, I sprayed a rubberized undercoating spray. Keep in mind that any coatings may limit grounding capability of the tank to the brackets, and you may want to make a ground wire modification like I did. Make sure you mask off areas that don’t need paint on them like the fill tube, vent tube, fuel inlet and outlet, and the connector for the fuel gauge. It is also a good time to replace the rubber components: fuel lines, vent line, fuel filler line, and mounting bushings.

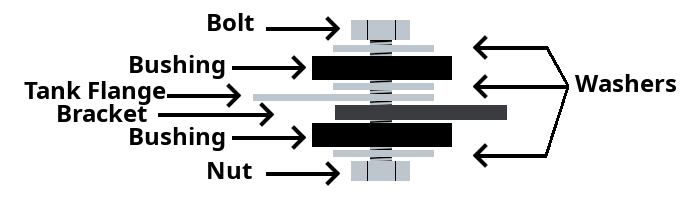

Mounting the tank is the opposite of removal. Install the rubber hoses to the tank for the fuel supply and return lines, as the tank top will be difficult to impossible to reach after the tank is lifted into place. Slide the tank back under the vehicle on the floor jack, and reconnect the fuel gauge wire. Lift the tank back into position with the jack, and rest on top of the two installed mounting brackets. Re-install the passenger rear bracket and line up the flange holes with the bracket holes. At this point the jack can be removed. Re-install the hardware in the order shown in the parts manual, as indicated in diagram 1. There should be 2 bushings, 3 washers, a 5/16″x24tpi bolt about 1-3/4″ long and a steel lock nut. Tighten the mounting bolts. Reconnect the fuel and return nylon lines to the previously installed rubber lines. Re-install the vent and fill hoses. Make sure all of the clamps are tight on all of the hoses.

Diagram 1 (Hardware Order)

At this point, the job is complete. Fill the tank and check for leaks around the fill and vent tubes. Start the engine and verify that the fuel pickup and return line connections don’t leak.

In the process of doing this job, I found a few areas of improvement. The original sending unit is held in with Phillips head machine screws with star washers. I replaced this hardware with Allen drive button head screws and new washers. I did this because the Phillips screws nearly stripped trying to remove them, and the Allen heads are better at not stripping under higher torque values. Additionally, the ground for the fuel gauge depends on the connection between the tank and the brackets. This can easily be compromised by corrosion or coatings. I added a ground line between on of the sending unit mounting screws and the frame to ensure a good ground. For the life of me, I cannot figure out why Jeep put the outlet and return lines on the passenger side of the tank, both the Hurricane F4 and the Dauntless V6 have their fuel pumps on the driver side. If you wanted extra durability, running copper-nickel lines from the tank to the front would limit the chances for punctures in the line, and you could eliminate the over-engine lines on the V6 and under engine line on the F4 by crossing over at a frame member near the tank and run up inside the frame rail.